As a leading manufacturer of special machines and complete lines for the surface finishing technology SPALECK Oberflächentechnik GmbH & Co. KG has been developing customized processes for the surface finishing for about 100 years for customers all over the world.

Next to the manufacture of standard machines such as round tub vibrators, drums as well as centrifugal finishing and through-feed machines SPALECK Oberflächentechnik GmbH & Co. KG is the specialist for combined surface finishing solutions with a high degree of automation. The complex processing techniques are complemented by a comprehensive choice of processing media. Applicants of the die casting, the chain and the mint industry as well as of the additive manufacturing industry rank among the international clientele of SPALECK Oberflächentechnik GmbH & Co. KG.

Spaleck Inspection Technology

In December 2021 SPALECK Oberflächentechnik GmbH & Co. KG took over the operations of InduVis GmbH. InduVis was specialized in the development of individual inspection solutions and high-quality sorting machines. With the takeover, SPALECK Oberflächentechnik GmbH & Co. KG can offer modules for the inspection of surface results achieved after the finishing process now.

SPALECK Oberflächentechnik has more than 25 years of experience in the international mint industry. Coin blanks require a very special surface finishing, one that has a positive impact on product properties such as mint quality and the coin’s service life, as well as minting dies. At the same time, by applying SPALECK Oberflächentechnik finishing solutions, you can economize your process costs to some extent and thus achieve considerable savings. SPALECK focuses on fully automated solutions equipped with sophisticated control technology and database connections. Integrating the automated infeed into existing production lines, inspecting of achieved surfaces and delivering or packaging the coin blanks are just as much part of our range of services as is the support concerning the process engineering and a resource-saving, environmentally friendly process water recycling.

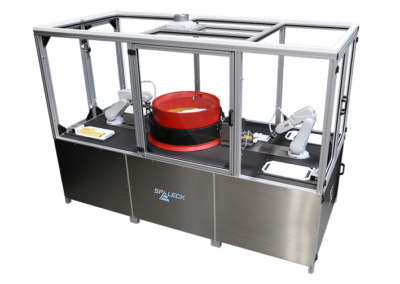

Die Cone Finisher

The surface finish of a die cone is essential for the quality of each coin that is minted. SPALECK technology guarantees a high quality standard, that is reproducible with every batch. Due to special polishing media and high energy generated by centrifugal force, die cones get the perfect preparation for the hobbing process.

Let us share our expererience…

Take a look at our brochures and get an idea of our product portfolio

Your contact partners

Thomas Hogenkamp Sales Director Mint Applications

Guido Tepasse Technical Service and Support

Elisa Boland Disposal and Sales of Surface Finishing Media

Nele Bruns Sales Mint Applications

Ingo Löken Sales Engineer

Thomas Tschirpke Surface Process Development

As a leading manufacturer of special machines and complete lines for the surface finishing technology SPALECK Oberflächentechnik GmbH & Co. KG has been developing customized processes for the surface finishing for about 100 years for customers all over the world.

Next to the manufacture of standard machines such as round tub vibrators, drums as well as centrifugal finishing and through-feed machines SPALECK Oberflächentechnik GmbH & Co. KG is the specialist for combined surface finishing solutions with a high degree of automation. The complex processing techniques are complemented by a comprehensive choice of processing media. Applicants of the die casting, the chain and the mint industry as well as of the additive manufacturing industry rank among the international clientele of SPALECK Oberflächentechnik GmbH & Co. KG.

Spaleck Inspection Technology

In December 2021 SPALECK Oberflächentechnik GmbH & Co. KG took over the operations of InduVis GmbH. InduVis was specialized in the development of individual inspection solutions and high-quality sorting machines. With the takeover, SPALECK Oberflächentechnik GmbH & Co. KG can offer modules for the inspection of surface results achieved after the finishing process now.

SPALECK Oberflächentechnik has more than 25 years of experience in the international mint industry. Coin blanks require a very special surface finishing, one that has a positive impact on product properties such as mint quality and the coin’s service life, as well as minting dies. At the same time, by applying SPALECK Oberflächentechnik finishing solutions, you can economize your process costs to some extent and thus achieve considerable savings. SPALECK focuses on fully automated solutions equipped with sophisticated control technology and database connections. Integrating the automated infeed into existing production lines, inspecting of achieved surfaces and delivering or packaging the coin blanks are just as much part of our range of services as is the support concerning the process engineering and a resource-saving, environmentally friendly process water recycling.

Die Cone Finisher

The surface finish of a die cone is essential for the quality of each coin that is minted. SPALECK technology guarantees a high quality standard, that is reproducible with every batch. Due to special polishing media and high energy generated by centrifugal force, die cones get the perfect preparation for the hobbing process.

Let us share our expererience…

Take a look at our brochures and get an idea of our product portfolio

Your contact partners

Thomas Hogenkamp Sales Director Mint Applications

Guido Tepasse Technical Service and Support

Elisa Boland Disposal and Sales of Surface Finishing Media

Nele Bruns Sales Mint Applications

Ingo Löken Sales Engineer

Thomas Tschirpke Surface Process Development