Coin presses from Sack & Kiesselbach shape the industry. When it comes to producing coins and medals of the highest minting quality, the wheat is separated from the chaff. Only a few manufacturers have mastered this discipline. Extreme quality requirements demand more than a perfectly designed press. The art lies in perfectly coordinating the smooth interaction of all components involved in the production process. This requires know-how and passion.

MPP-250: The new manual minting press 250to – everything you need for minting

Just visiting the Sack & Kiesselbach booth at the World Money Fair in Berlin would have been worth the trip again this year. Because we would have loved to present you the newest member of the Sack & Kiesselbach family live and in color.

With the MPP-250, we are entering a new dimension in the field of a 250to press with regard to budget, ergonomics and space requirements. Whether coins, bars, medals, jewelry or technical pressed parts: The MPP-250 is always just right.

And the best thing about it: You don’t have to do without anything – the well-known and proven Sack & Kiesselbach quality is also convincing with our youngest family member. Of course, the MPP-250 is also equipped with any type of customer-specific minting tool!

TMA-350: A new dimension in medal production

The table medal automat (TMA-350) combines the advantages of the oil-hydraulic presses with the completely new standards referring to automation and flexibility.

The base includes the genes of the legendary TMP (table medal press). For the development, we gathered our customers‘ requirements and ideas over many years and implemented them consequently.

Continuity in tool construction

The hobbing press (EP) is the cost-effective companion for the production of punches and dies.

Together with a precision hobbing tool, the EP impresses customers all over the world.

The highest level of accuracy is required for Centricity and stamp length when manufacturing production stamps.

Here we offer our customers the whole package for tool construction.

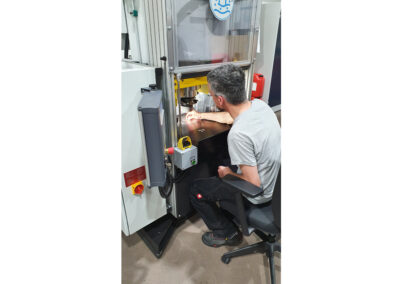

Communication 4.0 in Reality

The essential step towards “Industry 4.0” lies in the visualisation of reality in the digital-virtual world.

Virtual Reality, Augmented Reality and Assisted Reality make it possible to display the next machining step directly into the technician’s field of vision.

This allows production and maintenance processes to be essential optimised, which comes especially nowadays since early 2019 to much more importance.

Thanks to the Assisted Reality and with our new smart glasses, we can look over the shoulder of the operator. S&K has already taken up this topic in the years before 2020 and tested and evaluated the different techniques. Due to the circumstances in 2020, the leap of practical application was thus quickly implemented.

With an own at the machine integrated hotspot solution it allows also an online connection independent from a local network environment.

Coin presses from Sack & Kiesselbach shape the industry. When it comes to producing coins and medals of the highest minting quality, the wheat is separated from the chaff. Only a few manufacturers have mastered this discipline. Extreme quality requirements demand more than a perfectly designed press. The art lies in perfectly coordinating the smooth interaction of all components involved in the production process. This requires know-how and passion.

MPP-250: The new manual minting press 250to – everything you need for minting

Just visiting the Sack & Kiesselbach booth at the World Money Fair in Berlin would have been worth the trip again this year. Because we would have loved to present you the newest member of the Sack & Kiesselbach family live and in color.

With the MPP-250, we are entering a new dimension in the field of a 250to press with regard to budget, ergonomics and space requirements. Whether coins, bars, medals, jewelry or technical pressed parts: The MPP-250 is always just right.

And the best thing about it: You don’t have to do without anything – the well-known and proven Sack & Kiesselbach quality is also convincing with our youngest family member. Of course, the MPP-250 is also equipped with any type of customer-specific minting tool!

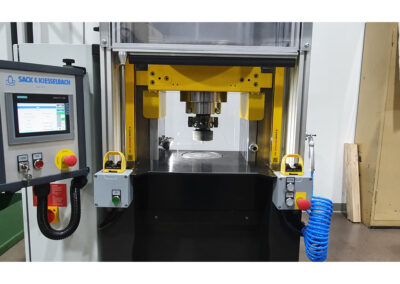

TMA-350: A new dimension in medal production

The table medal automat (TMA-350) combines the advantages of the oil-hydraulic presses with the completely new standards referring to automation and flexibility.

The base includes the genes of the legendary TMP (table medal press). For the development, we gathered our customers‘ requirements and ideas over many years and implemented them consequently.

Continuity in tool construction

The hobbing press (EP) is the cost-effective companion for the production of punches and dies.

Together with a precision hobbing tool, the EP impresses customers all over the world.

The highest level of accuracy is required for Centricity and stamp length when manufacturing production stamps.

Here we offer our customers the whole package for tool construction.

Communication 4.0 in Reality

The essential step towards “Industry 4.0” lies in the visualisation of reality in the digital-virtual world.

Virtual Reality, Augmented Reality and Assisted Reality make it possible to display the next machining step directly into the technician’s field of vision.

This allows production and maintenance processes to be essential optimised, which comes especially nowadays since early 2019 to much more importance.

Thanks to the Assisted Reality and with our new smart glasses, we can look over the shoulder of the operator. S&K has already taken up this topic in the years before 2020 and tested and evaluated the different techniques. Due to the circumstances in 2020, the leap of practical application was thus quickly implemented.

With an own at the machine integrated hotspot solution it allows also an online connection independent from a local network environment.

Sack & Kiesselbach Maschinenfabrik GmbH

Langster Straße 9

40668 Meerbusch, Germany